The Exact Science of

Pre-Fabrication

The future is here. At LORD, our projects begin with a robotic geospatial scan, that provides a bridge between real world constraints and design solutions. Our Pre-Construction Visualization team uses this information to generate as-builts, for existing components, taking into account exact, detailed dimensions and then build 3D models of our client's project. In the process, isometric drawings and 3D renderings proceed to break the project into its components and provide detailed piping and conduit spool drawings. Armed with this data, LORD's team at Precision Fabricators moves from concept to build.

Custom Fabrication

We will Design and Build the Right Part for Every Job

1. Gather Data

Our Pre-Construction Visualization Team uses the latest land surveying tools, including the Robotic Trimble Total Station.

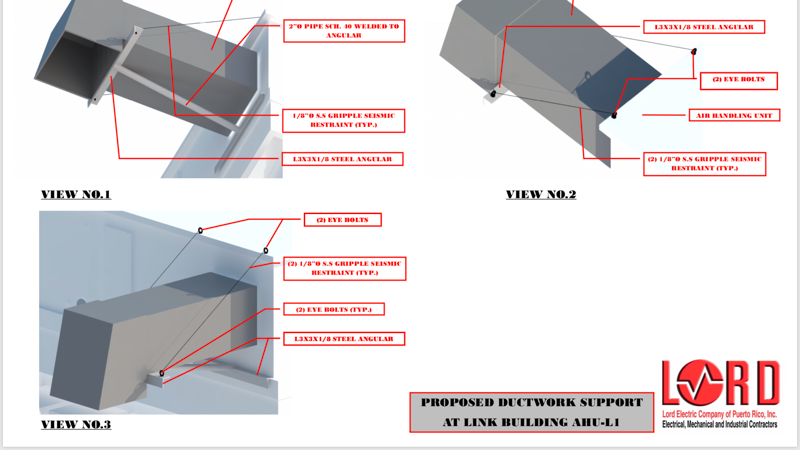

2. DESIGN the Solution

The digitized geospatial parameters and detailed equipment as-builts generated allow us to design the ideal components.

3. Build & Install

LORD has at its disposal a array of welding equipment for use in our facilities or on the field. We make sure the right tools are used matching the qualifications of each fabrication and installation.Orbital Tube Weld System

LORD's Orbital Welding facilities are unique in Puerto Rico. They are capable of performing automatic autogenous (GTAW, T1G) welding of tubes, fittings (such as Tri-clover, Alfa Laval, United, Advance or Top Line), elbows, return bends and think wall pipe from 1/8" to 4" O.D. It can also weld SCH. 10 stainless steel pipe. The Programmable Controls, Power Source and the range of tube sizes that can be welded, make this the most capable tube weld system available. We also have rugged welding systems that are designed for use in the field jobsite.

Orbital Tube Welding

LORD is the leader in Orbital Welding, our experienced welders and advanced equipment enable us to perform automatic autogenous welding with the exactitude of programmable controls inhouse and while on the field.

Conduits, Cables, & Receptacles

LORD's Pre-Fabrication team offers a total solution for cabling. We design conduit systems that match your needs, and build them to the exact length and bends. LORD will also craft the cable conductors and MC cables to the exact length and number of conductors required. To finalize the installation we can also build the receptacles, pre-wire them in metal stud assembly and provide the final assembled system, ready for use.